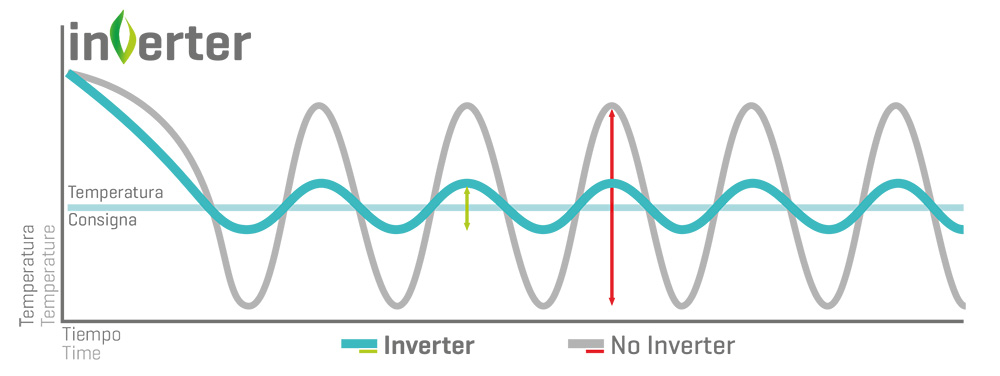

In conventional non-INVERTER equipment, the compressor runs at maximum speed until it reaches the set temperature, and once it is reached, it stops, repeating successively with continuous starts and stops, causing higher consumption and less temperature stability.

However, with INVERTER technology, once the compressor starts operating, it varies its speed to adapt to the temperature differential that exists at any given time, avoiding the compressor starting and stopping, which increases consumption and causes the temperature of the equipment to fluctuate more.